The Ultimate Guide to Stainless Steel Pipes: Types, Benefits, and Applications

Stainless steel pipes play a crucial role in construction, industrial applications, and infrastructure projects. They are widely used due to their strength, corrosion resistance, and longevity, making them ideal for plumbing, structural frameworks, fluid transport, and high-pressure applications.

In this guide, we’ll explore what stainless steel pipes are, how they’re manufactured, different types, key specifications, and their most common applications. We’ll also compare stainless steel pipes with other types of pipes to help you make an informed choice for your project.

What Are Stainless Steel Pipes?

Stainless steel pipes are hollow cylindrical tubes made from stainless steel, designed for transporting fluids, gases, and solids across various industries. Their exceptional resistance to rust, extreme temperatures, and mechanical stress makes them an ideal choice for industrial, commercial, and residential applications.

Why Use Stainless Steel Pipes?

✔ Corrosion Resistance – Withstands moisture, chemicals, and extreme temperatures.

✔ Durability & Strength – Maintains structural integrity in high-pressure environments.

✔ Low Maintenance – Resistant to rust, staining, and chemical damage.

✔ Hygienic & Non-Toxic – Ideal for food processing, medical, and pharmaceutical applications.

✔ Aesthetic & Versatile – Used in decorative and architectural structures for a sleek, modern appearance.

How Are Stainless Steel Pipes Manufactured?

The production of stainless steel pipes involves multiple stages to ensure precision, durability, and high-quality performance:

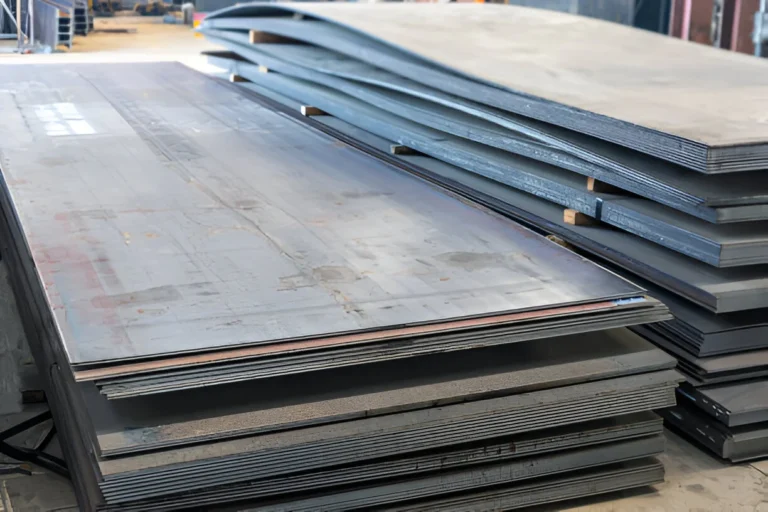

1. Raw Material Processing

- Stainless steel is made by melting raw materials like iron, chromium, nickel, and molybdenum in a furnace.

- The molten steel is cast into billets or slabs for further processing.

2. Pipe Formation

- Seamless Pipes: Created by piercing a solid billet and rolling it into a tube.

- Welded Pipes: Formed by bending stainless steel sheets into a cylindrical shape and welding the edges.

3. Heat Treatment & Annealing

- Pipes undergo annealing (heat treatment) to enhance flexibility, relieve internal stresses, and improve corrosion resistance.

4. Surface Treatment

- Pickling removes oxidation and impurities, while polishing improves surface smoothness.

- Finishes can range from matte, brushed, satin, to mirror-polished.

5. Cutting, Testing & Inspection

- Pipes are cut to required lengths and tested for leakage, pressure resistance, and structural integrity before shipping.

Different Types of Stainless Steel Pipes

There are various stainless steel pipes, each designed for specific applications:

1. Seamless Stainless Steel Pipes

✔ Made without any welds, ensuring a smooth and uniform structure.

✔ Used in high-pressure applications, oil refineries, and gas pipelines.

2. Welded Stainless Steel Pipes

✔ Formed by rolling and welding stainless steel sheets into a tube.

✔ Used in structural applications, water distribution, and mechanical industries.

3. Round Stainless Steel Pipes

✔ The most common shape, ideal for fluid transport, decorative applications, and piping systems.

4. Square & Rectangular Stainless Steel Pipes

✔ Used in architectural designs, building frameworks, and industrial equipment.

5. Duplex Stainless Steel Pipes

✔ Made from a combination of austenitic and ferritic stainless steel, offering higher strength and superior corrosion resistance.

✔ Commonly used in marine, offshore, and chemical industries.

Key Specifications of Stainless Steel Pipes

| Specification | Typical Range |

|---|---|

| Diameter | 1/8 inch – 48 inches |

| Wall Thickness | 0.5mm – 20mm |

| Length | 1000mm – 12000mm |

| Grades | 304, 316, 321, 410, 2205 |

| Surface Finishes | Polished, Satin, Mirror, Hairline |

Stainless Steel Pipes vs. Other Pipe Materials

Choosing the right type of pipe depends on application, budget, and environmental factors.

| Feature | Stainless Steel Pipe | Carbon Steel Pipe | PVC Pipe |

|---|---|---|---|

| Corrosion Resistance | Excellent (rust-proof) | Low (needs protective coating) | Moderate (prone to UV degradation) |

| Strength & Durability | High | High but susceptible to rust | Low, brittle under pressure |

| Temperature Resistance | Withstands extreme heat | Good but not as resistant | Weakens under high heat |

| Lifespan | 50+ years | 20-30 years | 10-25 years |

| Hygienic & Non-Toxic | Yes, ideal for food & medical | No (may corrode, affecting quality) | Yes, but may degrade over time |

| Cost | More expensive upfront | More affordable | Cheapest option |

When to Choose Stainless Steel Pipes

✔ For high-temperature, high-pressure, and corrosive environments.

✔ For industries that require strict hygiene standards (food, medical, pharmaceuticals).

✔ For applications demanding long-term durability and minimal maintenance.

When to Choose Other Pipes

✔ Carbon Steel Pipes – Suitable for industrial applications where cost is a priority.

✔ PVC Pipes – Best for low-pressure plumbing, drainage, and lightweight applications.

Applications of Stainless Steel Pipes

Stainless steel pipes are used across multiple industries due to their strength, versatility, and resistance to corrosion.

1. Construction & Architecture

- Used in handrails, support structures, and decorative elements.

- Found in modern building frameworks, bridges, and high-rise buildings.

2. Industrial & Manufacturing

- Essential in chemical processing plants, power plants, and factory systems.

- Used for transporting gases, liquids, and chemicals in industrial settings.

3. Oil & Gas Industry

- Used in pipelines, offshore drilling rigs, and petroleum refineries.

- Can withstand high pressure and extreme environmental conditions.

4. Automotive & Transportation

- Found in exhaust systems, fuel lines, and chassis reinforcements.

- Used in railway, aerospace, and shipbuilding industries.

5. Food Processing & Medical Equipment

- Ideal for sanitary water systems, pharmaceutical factories, and medical gas distribution.

- Used in hospitals, food manufacturing plants, and beverage processing systems.

Why Buy Stainless Steel Pipes from Baiyoung?

When sourcing stainless steel pipes, working with a reliable supplier is essential. Baiyoung offers:

1. High-Quality Products

✔ Stainless steel pipes that meet international industry standards.

2. Competitive Pricing

✔ Cost-effective solutions for bulk buyers and industrial users.

3. Wide Product Range

✔ Available in multiple grades, sizes, and finishes to meet various application needs.

4. Reliable & Fast Delivery

✔ Efficient logistics network ensuring on-time shipments worldwide.

5. Expert Support

✔ Professional guidance to help you select the best stainless steel pipes for your project.

Conclusion

Stainless steel pipes are a long-term investment for industrial, construction, and transportation applications. Their high strength, corrosion resistance, and versatility make them a preferred choice for demanding environments.

For top-quality stainless steel pipes, Baiyoung provides high-performance products, competitive pricing, and expert customer service. Contact Baiyoung today to find the best stainless steel solutions for your project!