Steel Pipes: The Smart Choice for Wholesale Buyers in Construction and Industry

Steel pipes are one of the most in-demand materials in the construction, industrial, and energy sectors. Known for their strength, durability, and versatility, steel pipes are essential in fluid transportation, structural frameworks, and high-pressure applications.

For wholesale buyers, contractors, and steel suppliers, sourcing high-quality steel pipes in bulk ensures cost efficiency, reliability, and long-term performance. This guide will help you understand the different types of steel pipes, their specifications, and their industrial applications, making it easier for you to make the right purchasing decision.

Why Are Steel Pipes Essential for Bulk Buyers?

Steel pipes are used in a wide range of applications, from underground pipelines to heavy machinery. Their ability to withstand pressure, heat, and environmental exposure makes them an ideal choice for large-scale projects.

Key Advantages for Wholesale Buyers

✔ Exceptional Strength & Durability – Withstands high pressure, temperature, and mechanical stress.

✔ Cost-Effective for Bulk Purchasing – Buying in large quantities lowers overall procurement costs.

✔ Corrosion & Weather Resistance – Available in galvanized and coated options for extended lifespan.

✔ Multiple Sizes & Grades Available – Customizable for specific industry requirements.

✔ Versatile Industrial Applications – Used in pipelines, construction, energy, and automotive sectors.

Types of Steel Pipes for Different Applications

Steel pipes come in various types and grades, each designed for specific industry needs.

1. Seamless Steel Pipe

✔ Manufactured without welding, providing a smooth interior and exterior finish.

✔ Ideal for high-pressure applications, such as oil and gas pipelines and boilers.

✔ Available in carbon steel, alloy steel, and stainless steel.

2. Welded Steel Pipe

✔ Produced by rolling and welding steel sheets into a tube shape.

✔ Common in structural applications, plumbing, and mechanical industries.

✔ More affordable than seamless pipes, making it an ideal choice for bulk orders.

3. Galvanized Steel Pipe

✔ Coated with zinc to prevent rust and corrosion.

✔ Used in water supply systems, outdoor fencing, and scaffolding.

✔ Available in seamless and welded options for various applications.

4. Stainless Steel Pipe

✔ Resistant to corrosion, heat, and chemical exposure.

✔ Used in food processing, medical equipment, and marine environments.

✔ Available in grades 304, 316, and 410 for different levels of corrosion resistance.

5. Carbon Steel Pipe

✔ High-strength and cost-effective solution for structural and fluid transportation needs.

✔ Used in oil & gas pipelines, heavy machinery, and industrial applications.

✔ Comes in both seamless and welded forms.

6. ERW (Electric Resistance Welded) Steel Pipe

✔ Manufactured using electrical resistance welding, ensuring strong, smooth seams.

✔ Commonly used in mechanical and structural applications.

✔ More economical than seamless pipes, making it ideal for large-scale projects.

Steel Pipe Specifications for Wholesale Buyers

| Specification | Typical Range |

|---|---|

| Diameter | 1/8 inch – 48 inches |

| Wall Thickness | 0.5mm – 20mm |

| Length | 1000mm – 12000mm |

| Grades Available | A53, A106, API 5L, ASTM A312, ASTM A500 |

| Coating Options | Galvanized, Epoxy, Black, PVC-Coated |

For high-pressure and outdoor applications, consider pipes with thicker walls and corrosion-resistant coatings.

Steel Pipes vs. Other Pipe Materials: Which Is the Best Choice?

For wholesale buyers, selecting the right pipe material depends on cost, durability, and intended use.

| Feature | Steel Pipe | PVC Pipe | Copper Pipe |

|---|---|---|---|

| Strength & Durability | High | Low | Moderate |

| Corrosion Resistance | High (Coated/Galvanized) | High | Excellent |

| Weight | Heavy | Lightweight | Moderate |

| Cost | Cost-Effective for Bulk | Cheap | Expensive |

| Common Uses | Industrial, Construction, Oil & Gas | Plumbing, Drainage, Ventilation | HVAC, Water Supply, Medical Use |

When to Choose Steel Pipes

✔ For high-pressure applications in oil, gas, and water transmission.

✔ For long-term durability in industrial and construction projects.

✔ For environments where corrosion resistance and strength are crucial.

When to Consider Other Materials

✔ PVC Pipes – Best for low-cost, lightweight plumbing and drainage systems.

✔ Copper Pipes – Preferred for HVAC, medical gas supply, and clean water systems.

Industries That Depend on Steel Pipes

1. Construction & Infrastructure

✔ Used in steel frameworks, underground pipelines, and scaffolding.

✔ Provides long-term stability in large structures.

2. Oil & Gas Industry

✔ Essential for oil refineries, offshore platforms, and gas pipelines.

✔ Designed to withstand high pressure and harsh environmental conditions.

3. Industrial & Manufacturing

✔ Found in boilers, heat exchangers, and heavy-duty machinery.

✔ Handles high-temperature and high-stress environments.

4. Water & Sewage Systems

✔ Used in municipal water supply, sewage treatment plants, and industrial drainage.

✔ Available in protective coatings for added durability.

5. Automotive & Transportation

✔ Used in exhaust systems, fuel lines, and chassis reinforcements.

✔ Withstands extreme heat and mechanical stress.

Why Choose Baiyoung for Wholesale Steel Pipes?

1. Premium Quality with Industry Certifications

✔ Complies with ISO, ASTM, and API standards for guaranteed quality.

2. Competitive Wholesale Pricing

✔ Affordable bulk rates for steel distributors, manufacturers, and contractors.

3. Wide Range of Steel Pipe Types

✔ Available in seamless, welded, galvanized, and stainless steel options.

4. Fast & Reliable Global Shipping

✔ Strong logistics network ensures on-time delivery to major markets worldwide.

5. Expert Technical Support & Custom Orders

✔ Professional assistance for custom specifications, coatings, and bulk requirements.

Final Thoughts

Steel pipes are a fundamental component of industrial, construction, and infrastructure projects, offering exceptional strength, reliability, and cost-effectiveness. Whether you need carbon steel, stainless steel, or galvanized pipes, partnering with a trusted supplier ensures top-quality products and long-term value.

For high-quality steel pipes at competitive wholesale prices, Baiyoung delivers certified products, fast shipping, and expert customer support. Contact Baiyoung today to discuss your bulk steel pipe requirements!

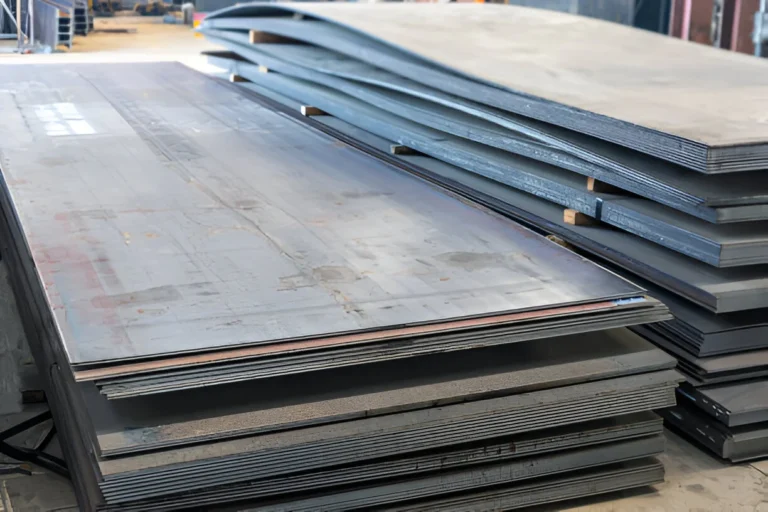

Cold rolled steel is one of the most widely used materials in manufacturing, construction, and industrial applications. Known for its smooth surface, high strength, and dimensional accuracy, cold rolled steel is a go-to choice for projects that require precision, durability, and a polished finish.

In this guide, we’ll break down what cold rolled steel is, how it’s made, its key properties, different types, and its most common applications. Plus, we’ll compare it with hot rolled steel so you can make the best choice for your next project.

What Is Cold Rolled Steel?

Cold rolled steel is steel that has been processed at room temperature after being hot rolled. This extra step improves surface quality, strength, and precision, making it ideal for applications that demand tight tolerances and a smooth finish.

Unlike hot rolled steel, which has a rough and scaly surface, cold rolled steel is refined and uniform, making it a perfect choice for automobiles, appliances, precision components, and construction materials.

Key Benefits of Cold Rolled Steel

✔ Stronger & Harder – Work-hardening during the rolling process increases strength and durability.

✔ Smoother Finish – No oxide scale, making it ideal for painting, plating, and coating.

✔ More Precise Dimensions – Cold rolling results in tighter tolerances and uniform thickness.

✔ Better Formability – Easier to bend, shape, and fabricate compared to hot rolled steel.

How Is Cold Rolled Steel Made?

Cold rolled steel goes through several steps before it reaches its final form:

Step 1: Hot Rolling

- Steel is heated above 1,700°F (930°C) and passed through rollers to reduce thickness.

- At this stage, it has a rough, uneven surface with scale and impurities.

Step 2: Pickling

- The hot rolled steel is cleaned using an acid bath to remove scale and oxidation.

- This process prepares the surface for the cold rolling stage.

Step 3: Cold Rolling

- The steel is rolled at room temperature to further refine thickness, surface finish, and mechanical properties.

- This step makes the steel harder, stronger, and smoother.

Step 4: Annealing (Optional)

- If flexibility is needed, the steel is heat-treated to restore ductility.

- Annealed cold rolled steel is easier to bend and shape.

Step 5: Final Processing

- The steel may be cut, coated, or further processed based on customer requirements.

Types of Cold Rolled Steel

Cold rolled steel comes in several forms, each suited for specific applications:

1. Cold Rolled Steel Sheets & Plates

- Used in automotive panels, appliances, furniture, and structural components.

- Available in various thicknesses for different industrial needs.

2. Cold Rolled Steel Coils

- Large sheets rolled into coils for easy transportation and processing.

- Commonly used in roofing, precision stamping, and construction reinforcements.

3. Cold Rolled Steel Bars

- Available in round, square, and flat bar forms.

- Used in machinery, fasteners, and building reinforcements.

4. Cold Rolled Steel Tubes & Pipes

- High-precision steel tubes for automotive, industrial, and engineering applications.

- Ideal for frames, support structures, and pipelines.

Common Specifications for Cold Rolled Steel

| Specification | Typical Range |

|---|---|

| Thickness | 0.3mm – 3mm (Sheets & Plates) |

| Width | 600mm – 2000mm (Coils & Sheets) |

| Length | 1000mm – 6000mm (Plates & Sheets) |

| Weight (Coils) | 1 – 10 tons per coil |

| Grades | SPCC, DC01, ASTM A1008, Q195, Q235 |

Cold Rolled Steel vs. Hot Rolled Steel: What’s the Difference?

Many people wonder whether to choose cold rolled steel or hot rolled steel. Let’s break down the key differences:

| Feature | Cold Rolled Steel | Hot Rolled Steel |

|---|---|---|

| Processing Temperature | Rolled at room temperature | Heated above 1,700°F (930°C) |

| Surface Finish | Smooth, polished, and uniform | Rough, with a scaly surface |

| Strength & Hardness | Higher due to work hardening | Strong but more ductile |

| Precision | High dimensional accuracy | Less precise due to cooling shrinkage |

| Cost | More expensive due to extra processing | More affordable |

| Common Uses | Automotive, appliances, construction | Structural beams, heavy equipment |

When to Choose Cold Rolled Steel

✔ For applications that need precision and a clean, polished surface.

✔ For automotive parts, appliances, and electrical enclosures.

✔ For industries where strength and uniform thickness are critical.

When to Choose Hot Rolled Steel

✔ For structural applications where surface quality is not a priority.

✔ For projects where cost is a bigger concern than precision.

✔ For welding and fabrication processes.

Applications of Cold Rolled Steel

Cold rolled steel is used in a wide range of industries, including:

1. Automotive & Transportation

- Used in car bodies, chassis components, and engine parts.

- Provides high strength and corrosion resistance for long-term durability.

2. Home Appliances & Electronics

- Found in refrigerators, washing machines, and ovens.

- Used for computer casings, electrical cabinets, and metal furniture.

3. Construction & Industrial Use

- Used for roofing, metal framing, and precision structural parts.

- Found in door frames, partitions, and interior paneling.

Surface Treatments for Cold Rolled Steel

To enhance durability and corrosion resistance, cold rolled steel often undergoes additional treatments:

1. Galvanization

- A protective zinc coating prevents rust, making it perfect for outdoor applications.

2. Painting or Powder Coating

- Improves aesthetic appeal and adds an extra layer of protection.

3. Plating (Nickel, Chrome, etc.)

- Common in automobiles, electronics, and decorative steel products.

Why Choose Baiyoung for Cold Rolled Steel?

When sourcing cold rolled steel, it’s crucial to work with a trusted supplier that offers high-quality products and reliable service.

1. Superior Quality

✔ Baiyoung provides premium-grade cold rolled steel that meets industry standards.

2. Competitive Pricing

✔ Affordable wholesale rates for bulk buyers and manufacturers.

3. Wide Product Selection

✔ Available in coils, sheets, plates, bars, and tubes to meet various industry needs.

4. Fast & Reliable Delivery

✔ Efficient logistics network ensures on-time shipments.

5. Expert Customer Support

✔ Professional guidance to help you choose the best steel for your application.

Conclusion

Cold rolled steel is an essential material for precision manufacturing, construction, and industrial applications. With its smooth surface, high strength, and excellent dimensional accuracy, it remains a top choice for automotive, appliance, and engineering industries.

For high-quality cold rolled steel, Baiyoung is a trusted supplier offering competitive prices, excellent service, and fast delivery. Contact Baiyoung today for all your steel needs!