Everything You Need to Know About Stainless Steel Wire: Uses, Types, and Advantages

Stainless steel wire is a highly versatile material used across multiple industries, including construction, manufacturing, automotive, and marine applications. With its high tensile strength, corrosion resistance, and durability, stainless steel wire is an essential component in everything from welding and fencing to medical devices and suspension bridges.

In this guide, we’ll explore what stainless steel wire is, its manufacturing process, different types, key specifications, and common applications. We’ll also compare it with other wire materials so you can make an informed choice for your needs.

What Is Stainless Steel Wire?

Stainless steel wire is a thin, flexible, and high-strength metal strand made from stainless steel alloys. Available in various thicknesses and finishes, it is used in reinforcement, industrial manufacturing, electrical wiring, and security fencing.

What makes stainless steel wire stand out? Its combination of strength, flexibility, and resistance to corrosion, making it ideal for demanding environments where durability and performance matter.

Why Choose Stainless Steel Wire?

✔ Rust & Corrosion Resistant – Withstands moisture, chemicals, and extreme weather.

✔ High Tensile Strength – Handles heavy loads and mechanical stress without breaking.

✔ Long-Lasting & Low Maintenance – Doesn’t degrade over time like other metals.

✔ Flexible & Ductile – Easy to bend, shape, and process for different uses.

✔ Hygienic & Safe – Used in medical, food processing, and cleanroom environments.

How Is Stainless Steel Wire Made?

The production process ensures that stainless steel wire meets high industry standards for strength, flexibility, and corrosion resistance.

Step 1: Raw Material Preparation

- Stainless steel is produced by melting iron, chromium, nickel, and other alloys in a furnace.

- The molten steel is cast into rods or billets for further processing.

Step 2: Hot Rolling & Wire Drawing

- The steel rods are heated and rolled into thinner strands.

- The strands are pulled through dies of progressively smaller sizes to achieve the required diameter.

Step 3: Annealing & Heat Treatment

- The wire is heat-treated (annealed) to enhance flexibility and workability.

- This step ensures optimal strength and ductility for various applications.

Step 4: Surface Finishing & Coating

- The wire is treated through pickling, polishing, or coating (PVC, nylon, or galvanized finishes).

- Different finishes provide extra corrosion resistance or aesthetic appeal.

Step 5: Cutting & Coiling

- The final wire is cut to length or wound into coils, ready for distribution.

Types of Stainless Steel Wire

Stainless steel wire comes in multiple varieties, each designed for specific applications.

1. Stainless Steel Spring Wire

✔ High elasticity and resilience.

✔ Used in springs, fasteners, and automotive components.

2. Stainless Steel Welding Wire

✔ Available for MIG, TIG, and arc welding.

✔ Offers strong and corrosion-resistant welds.

3. Stainless Steel Braided Wire

✔ Multiple strands woven together for added strength and flexibility.

✔ Used in electrical shielding, protective sleeving, and flexible connectors.

4. Stainless Steel Knitted Wire

✔ Interlocked loops form a mesh-like structure.

✔ Common in filtration systems, gaskets, and industrial cleaning equipment.

5. Stainless Steel Binding Wire

✔ Soft and pliable, perfect for binding, tying, and securing materials.

✔ Used in construction, agriculture, and landscaping.

6. Stainless Steel Rope Wire (Cable Wire)

✔ Composed of multiple strands twisted together for heavy-duty load-bearing.

✔ Used in suspension bridges, marine rigging, and industrial lifting applications.

Common Specifications of Stainless Steel Wire

| Specification | Typical Range |

|---|---|

| Diameter | 0.1mm – 10mm |

| Tensile Strength | 500 – 2000 MPa |

| Length | Custom lengths or supplied in coils |

| Grades | 304, 316, 321, 410, 2205 |

| Surface Finishes | Bright, Matte, Galvanized, PVC/Nylon Coated |

How Does Stainless Steel Wire Compare to Other Wire Materials?

Choosing the right wire depends on environmental conditions, mechanical strength, and corrosion resistance.

| Feature | Stainless Steel Wire | Carbon Steel Wire | Galvanized Wire |

|---|---|---|---|

| Corrosion Resistance | Excellent (rust-proof) | Low (needs coating) | Moderate (coating wears off) |

| Strength & Durability | High | High but prone to rust | Moderate, weakens over time |

| Flexibility | Good | Moderate | Moderate |

| Temperature Resistance | Withstands extreme heat | Weakens under high heat | Not suitable for high temperatures |

| Lifespan | 50+ years | 10-20 years | 15-25 years |

| Cost | Higher upfront investment | More affordable | Budget-friendly |

When to Choose Stainless Steel Wire

✔ For marine, outdoor, and chemical environments where corrosion resistance is critical.

✔ For high-strength applications requiring durability and flexibility.

✔ For hygiene-sensitive industries (food, medical, pharmaceuticals).

When to Choose Other Wire Types

✔ Carbon Steel Wire – Best for budget-friendly industrial applications.

✔ Galvanized Wire – Ideal for fencing, security barriers, and temporary reinforcements.

Where Is Stainless Steel Wire Used?

Stainless steel wire is a staple material in multiple industries, thanks to its resistance to corrosion, high strength, and versatility.

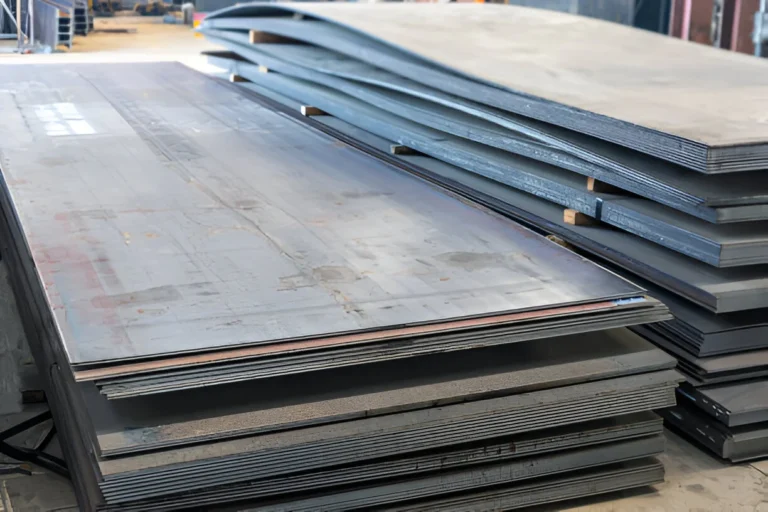

1. Construction & Architecture

- Used in reinforcement, binding, fencing, and safety barriers.

- Common in suspension bridges, support cables, and architectural designs.

2. Industrial & Manufacturing

- Essential for machinery components, springs, and conveyor belts.

- Used in filtration systems, woven mesh, and electrical shielding.

3. Automotive & Aerospace

- Found in exhaust systems, safety cables, and precision components.

- Used in aircraft cables, landing gear systems, and vibration dampeners.

4. Marine & Offshore Applications

- Ideal for boat rigging, mooring lines, and corrosion-resistant fasteners.

- Withstands saltwater exposure and extreme weather conditions.

5. Medical & Food Processing

- Used in surgical instruments, orthodontic braces, and sterilization trays.

- Meets hygiene regulations for food safety and cleanroom applications.

Why Buy Stainless Steel Wire from Baiyoung?

Baiyoung is a trusted supplier of premium stainless steel wire, offering:

1. High-Quality Materials

✔ Stainless steel wire that meets international quality standards.

2. Competitive Pricing

✔ Affordable wholesale rates for industrial and commercial buyers.

3. Wide Product Range

✔ Available in multiple grades, diameters, and coatings for diverse applications.

4. Reliable & Fast Delivery

✔ A well-established logistics network ensures timely shipments worldwide.

5. Expert Customer Support

✔ Professional guidance to help you choose the best stainless steel wire for your needs.

Conclusion

Stainless steel wire is a versatile, durable, and corrosion-resistant material used in construction, industrial, and precision applications. Its high strength, flexibility, and long lifespan make it the best choice for demanding environments.

For high-quality stainless steel wire, Baiyoung offers superior products, competitive pricing, and expert customer service. Contact Baiyoung today to find the perfect stainless steel solution for your project!