A Complete Guide to Stainless Steel Coils: Uses, Benefits, and Applications

Stainless steel coils are an essential material in modern industries, widely used in construction, manufacturing, and transportation. Known for their exceptional durability, corrosion resistance, and versatility, stainless steel coils are used in everything from building structures to industrial machinery and automotive components.

In this guide, we’ll take a closer look at what stainless steel coils are, how they’re made, their different types, key specifications, and their most common applications. We’ll also compare them with other types of steel coils so you can choose the right material for your project.

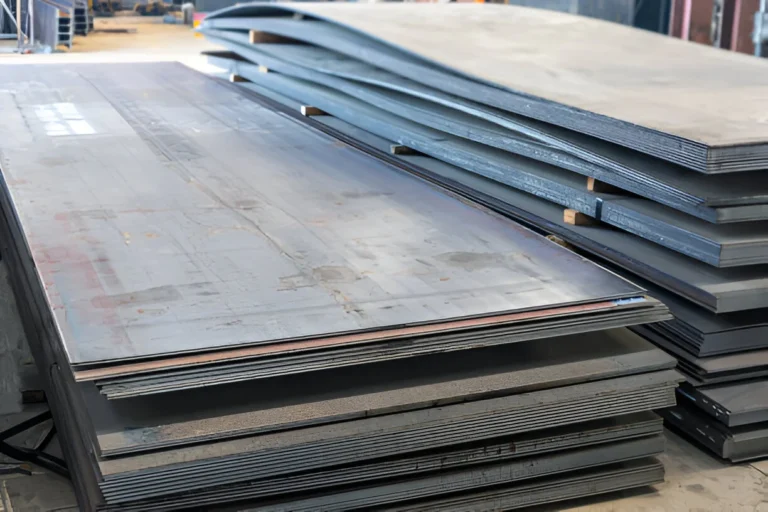

What Are Stainless Steel Coils?

Stainless steel coils are large sheets of stainless steel rolled into coils, making them easy to transport, store, and process. They maintain all the advantages of stainless steel, including high strength, excellent corrosion resistance, and a sleek, polished appearance.

Available in different grades, thicknesses, and surface finishes, stainless steel coils are widely used in construction, automotive, and industrial applications where reliability and longevity are essential.

Why Choose Stainless Steel Coils?

✔ Exceptional Corrosion Resistance – Ideal for use in harsh environments, including coastal and industrial areas.

✔ High Strength & Durability – Long-lasting and resistant to wear, impact, and extreme temperatures.

✔ Easy to Fabricate – Can be cut, welded, and shaped for a wide range of uses.

✔ Low Maintenance – Requires minimal upkeep, making it a cost-effective long-term solution.

✔ Sleek & Modern Appearance – Stainless steel’s polished look enhances aesthetic appeal in architectural applications.

How Are Stainless Steel Coils Made?

The manufacturing process of stainless steel coils involves multiple steps to ensure high quality, strength, and precision:

Step 1: Melting & Casting

- Raw materials, including iron, chromium, nickel, and other alloys, are melted together in a furnace.

- The molten metal is cast into slabs or billets.

Step 2: Hot Rolling

- The slabs are heated to over 1,700°F (930°C) and rolled into thinner sheets.

- At this stage, the steel takes shape but has a rough surface with oxidation and scale.

Step 3: Pickling & Annealing

- The steel is treated with acid (pickling) to remove oxidation and surface impurities.

- Annealing (heat treatment) helps relieve internal stresses and improve flexibility.

Step 4: Cold Rolling (Optional)

- For high-precision applications, the steel undergoes cold rolling, increasing strength and surface smoothness.

Step 5: Cutting & Coiling

- The final stainless steel sheet is cut into the required widths and rolled into coils.

- Coils are then packaged and shipped for further processing or direct use.

Types of Stainless Steel Coils

Stainless steel coils come in various grades, each designed for specific applications.

1. Austenitic Stainless Steel Coils (300 Series)

- The most common type, with high levels of chromium and nickel.

- Excellent corrosion resistance, ductility, and weldability.

- Common grades: 304, 316, 321.

2. Ferritic Stainless Steel Coils (400 Series)

- Magnetic and more affordable than austenitic stainless steel.

- Good corrosion resistance but lower strength and flexibility.

- Common grades: 430, 409, 439.

3. Martensitic Stainless Steel Coils

- High strength and hardness but less corrosion resistance.

- Used in applications requiring wear resistance.

- Common grades: 410, 420, 440C.

4. Duplex Stainless Steel Coils

- A mix of austenitic and ferritic stainless steel.

- Offers superior strength and excellent stress corrosion resistance.

- Common grades: 2205, 2507.

Common Specifications of Stainless Steel Coils

| Specification | Typical Range |

|---|---|

| Thickness | 0.3mm – 10mm |

| Width | 600mm – 2000mm |

| Coil Weight | 1 – 20 tons per coil |

| Grades | 304, 316, 430, 410, 2205 |

| Surface Finishes | 2B, BA, No.4, Mirror, Hairline |

Stainless Steel Coils vs. Other Steel Coils

How do stainless steel coils compare to hot rolled and cold rolled steel coils? Let’s break it down:

| Feature | Stainless Steel Coil | Hot Rolled Steel Coil | Cold Rolled Steel Coil |

|---|---|---|---|

| Corrosion Resistance | Excellent (high chromium content) | Moderate (may rust if untreated) | Low (requires coating for protection) |

| Strength | High | Good but less than stainless steel | Stronger than hot rolled due to work hardening |

| Surface Finish | Smooth and polished | Rough and scaly | Smooth and precise |

| Cost | More expensive due to alloy content | Most affordable | More expensive than hot rolled steel |

| Common Uses | Construction, industrial, marine | Structural, heavy machinery | Automotive, precision tools |

When to Choose Stainless Steel Coils

✔ For applications exposed to moisture, chemicals, or extreme temperatures.

✔ For decorative and architectural designs requiring a polished look.

✔ For industrial, medical, and food processing industries requiring high hygiene standards.

When to Choose Hot Rolled or Cold Rolled Steel Coils

✔ Hot Rolled Steel Coils – Best for structural and heavy-duty applications where surface finish isn’t a concern.

✔ Cold Rolled Steel Coils – Ideal for automotive, appliances, and precision engineering where smoothness and accuracy matter.

Applications of Stainless Steel Coils

Stainless steel coils are used in a variety of industries due to their strength, versatility, and resistance to corrosion.

1. Construction & Architecture

- Used in roofing, cladding, and structural support.

- Found in decorative panels, handrails, and building façades.

2. Automotive & Transportation

- Used in exhaust systems, fuel tanks, and structural reinforcements.

- Common in truck, train, and aerospace applications requiring durability.

3. Industrial & Manufacturing

- Essential in chemical processing plants, power stations, and machinery.

- Used in heat exchangers, tanks, and industrial pipelines.

4. Food & Medical Equipment

- Ideal for kitchen appliances, food processing machines, and medical tools.

- Non-reactive and easy to clean, ensuring hygiene standards are met.

Why Buy Stainless Steel Coils from Baiyoung?

When sourcing stainless steel coils, working with a reliable supplier is key. Baiyoung is a top provider, offering:

1. High-Quality Products

✔ Stainless steel coils that meet global quality standards.

2. Competitive Pricing

✔ Affordable wholesale rates for bulk orders and industrial buyers.

3. Wide Product Range

✔ Available in multiple grades, sizes, and finishes.

4. Reliable & Fast Delivery

✔ Efficient supply chain ensuring on-time shipments worldwide.

5. Expert Support

✔ Professional guidance to help you select the best material for your needs.

Conclusion

Stainless steel coils are an essential material in construction, manufacturing, and industrial applications. Their corrosion resistance, durability, and versatility make them a smart investment for long-term performance.

For premium stainless steel coils, Baiyoung provides high-quality products, competitive pricing, and expert customer service. Contact Baiyoung today for the best stainless steel solutions!