A Complete Guide to Hot Rolled Steel for Construction and Industrial Applications

Hot rolled steel is a fundamental material in construction, infrastructure, and industrial manufacturing. With its durability, cost-effectiveness, and versatility, hot rolled steel is widely used in structural frameworks, machinery, and large-scale infrastructure projects. This guide explores the different types of hot rolled steel, its production process, key specifications, and how it compares to cold rolled steel.

What Is Hot Rolled Steel?

Hot rolled steel is a type of steel that is processed at high temperatures, typically above 1,700°F (930°C), which is above its recrystallization point. This makes the material easier to shape, form, and manufacture into a variety of steel products. After rolling, the steel is left to cool at room temperature, giving it a rough, scaly surface.

Key Characteristics of Hot Rolled Steel

- Strong and durable – Ideal for structural and industrial applications.

- Cost-effective – More affordable than cold rolled steel due to its simpler production process.

- Easy to work with – Ductile and highly adaptable for welding, bending, and fabrication.

- Slightly imprecise dimensions – As the steel cools, minor shrinkage and deformations occur, making it less dimensionally precise than cold rolled steel.

Types of Hot Rolled Steel

Hot rolled steel is available in different forms, each tailored for specific applications:

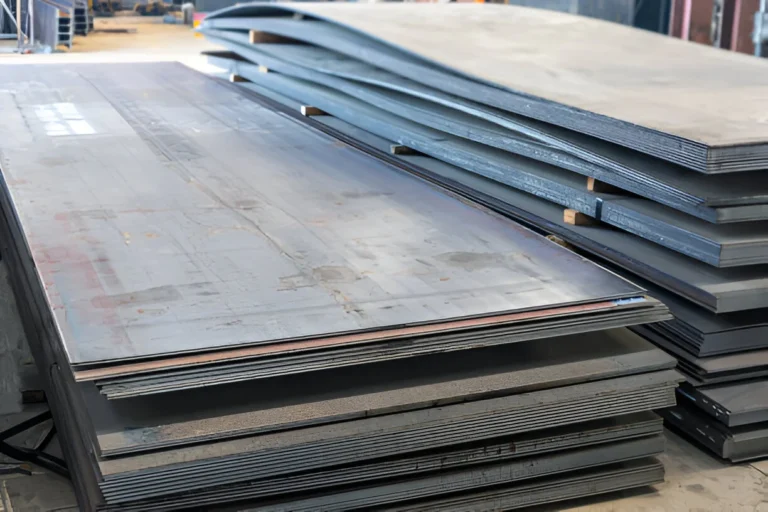

1. Hot Rolled Steel Sheets and Plates

- Used for construction, shipbuilding, and heavy machinery.

- Plates are thicker and stronger, while sheets are thinner and more flexible.

2. Hot Rolled Steel Coils

- Large sheets of steel rolled into coils for easy transportation and processing.

- Used in automotive manufacturing, pipelines, and roofing.

3. Hot Rolled Steel Bars

- Available in round, square, and flat bar forms.

- Used for reinforcement, fabrication, and mechanical components.

4. Hot Rolled Steel Beams

- Includes I-beams, H-beams, and U-channels.

- Essential for structural frames, bridges, and warehouses.

5. Hot Rolled Steel Tubes and Pipes

- Commonly used for gas pipelines, structural supports, and mechanical applications.

Hot Rolled Steel Specifications

Below are the typical specifications for hot rolled steel:

| Specification | Range |

|---|---|

| Thickness | 1.2mm – 100mm (Sheets & Plates) |

| Width | 600mm – 2000mm (Coils & Sheets) |

| Length | 1000mm – 12000mm (Plates & Sheets) |

| Weight (Coils) | 1.5 – 20 tons per coil |

| Grades | Q235, Q345, ASTM A36, A572, S235JR, S355JR, SS400 |

The choice of grade depends on the required strength, corrosion resistance, and application.

Hot Rolled Steel vs. Cold Rolled Steel

While both hot rolled and cold rolled steel have important uses, they differ in processing and application.

| Feature | Hot Rolled Steel | Cold Rolled Steel |

|---|---|---|

| Processing Temperature | Above 1,700°F (930°C) | Below recrystallization temperature |

| Surface Finish | Rough, with mill scale | Smooth, polished finish |

| Strength | Strong but more ductile | Stronger, harder due to cold working |

| Dimensional Accuracy | Less precise due to cooling shrinkage | More precise, consistent thickness |

| Cost | More affordable | More expensive due to additional processing |

| Common Uses | Construction beams, machinery, pipelines | Automotive parts, appliances, precision components |

When to Choose Hot Rolled Steel

- Ideal for large-scale structural applications where minor surface imperfections are not an issue.

- Suitable for projects that require heavy-duty steel at a lower cost.

- Works well in welding and fabrication processes due to its ductility.

When to Choose Cold Rolled Steel

- Best for applications requiring tight tolerances and a smooth finish.

- Ideal for automotive parts, precision tools, and home appliances.

- Preferred when dimensional accuracy is a priority.

Hot Rolled Steel Coils vs. Cold Rolled Steel Coils

Steel coils are widely used in construction and manufacturing, but hot rolled and cold rolled coils serve different purposes.

| Feature | Hot Rolled Steel Coil | Cold Rolled Steel Coil |

|---|---|---|

| Production Process | Hot rolled at high temperatures | Further processed from hot rolled steel |

| Surface Finish | Rough, with oxide scale | Smooth, polished, and precise |

| Thickness Range | 1.5mm – 20mm | 0.3mm – 3mm |

| Common Uses | Structural applications, pipelines | Automotive, electronics, home appliances |

Hot rolled steel coils are used for roofing, industrial machinery, and construction, while cold rolled coils are ideal for precision applications.

Applications of Hot Rolled Steel in Construction

Hot rolled steel is a crucial material in the construction industry due to its strength and affordability.

1. Structural Components

- Steel Beams – Used in high-rise buildings, bridges, and industrial warehouses.

- Columns and Frames – Essential for supporting load-bearing structures.

- Pipes and Tubes – Used in plumbing, gas lines, and mechanical frameworks.

2. Infrastructure and Industrial Construction

- Rail Tracks – Hot rolled steel is used for railway infrastructure due to its durability.

- Bridges and Highways – Provides structural integrity for road and bridge construction.

3. Heavy Equipment and Machinery

- Used in factory buildings, transportation, and heavy machinery components.

Surface Treatments for Hot Rolled Steel

Hot rolled steel often undergoes treatments to enhance its durability and appearance.

1. Pickling and Oiling

- Pickling removes oxide scale, preparing the steel for further processing.

- Oiling prevents rust and corrosion.

2. Galvanization

- Zinc coating improves resistance to rust, ideal for outdoor structures.

3. Painting or Powder Coating

- Adds aesthetic appeal and protects against environmental exposure.

How to Choose the Right Hot Rolled Steel for Your Project

- Thickness & Size – Choose based on load requirements and structural applications.

- Steel Grade – Different grades offer varying strength and corrosion resistance.

- Surface Treatment – Pickled, galvanized, or coated steel may be needed for specific environments.

Why Buy Hot Rolled Steel from Baiyoung?

Baiyoung is a trusted supplier of hot rolled steel, offering:

1. High-Quality Products

- Steel that meets international industry standards for strength and durability.

2. Competitive Pricing

- Affordable wholesale prices for large-scale construction projects.

3. Wide Product Range

- Available in coils, sheets, plates, bars, beams, and pipes.

4. Fast and Reliable Delivery

- Efficient logistics network ensures on-time delivery.

5. Excellent Customer Support

- Professional guidance to help you select the right steel products.

Conclusion

Hot rolled steel remains a key material for construction, manufacturing, and industrial applications due to its strength, affordability, and versatility. Whether for structural frameworks, heavy machinery, or large infrastructure projects, hot rolled steel offers long-lasting performance.

For high-quality hot rolled steel, Baiyoung provides premium products, competitive prices, and expert customer service. Whether you need steel beams, coils, or customized sheets, Baiyoung is your reliable partner for all your steel needs.